With the rapid development of smart terminals, industrial automation, and self-service devices, the precision and reliability of custom metal enclosures directly determine the market competitiveness of the final products.

Based on the manufacturing practices of ShiJie, this article systematically analyzes the 8-step standardized manufacturing process from design input to final product delivery. We focus on key process control points and industry technical standards, providing professional reference for engineers and procurement decision-makers.

Step 1: Design Review & DFM Engineering Optimization

Technical Standards:

According to GB/T 11344-2021 and ASME Y14.5 standards, conduct three-dimensional reviews of customer drawings, focusing on structural feasibility, tolerance reasonability, and process adaptability.

Pay particular attention to potential risks such as sharp angles, small bending radii, and weld accessibility.

Quality Control Points:

- The minimum internal radius of bending areas should be ≥ material thickness (R ≥ t) to avoid cracking.

- Tolerances for mounting holes should be controlled within ±0.15mm to ensure precise module assembly.

- Outdoor models must include drainage structures and sealing grooves to enhance IP protection reliability.

Step 2: Material Selection & Incoming Inspection

Technical Standards:

Strict material certification according to ASTM, JIS, and GB standards: 304/316 स्टेनलेस स्टील (ASTM A240), 5052/6061 aluminum alloy (ASTM B209), SPCC cold-rolled steel (JIS G3141).

Material Test Reports (MTR) are required for each batch, with spectrometer testing for composition verification.

Quality Control Points:

- Surface quality: No scratches, oxidation spots, or roller marks (refer to ASTM A480).

- Thickness tolerance: Stainless steel ±0.05mm, aluminum ±0.03mm (per GB/T 708).

- For food-grade applications, an EC 1935/2004 compliance declaration and surface roughness testing (Ra ≤ 0.8μm) are required.

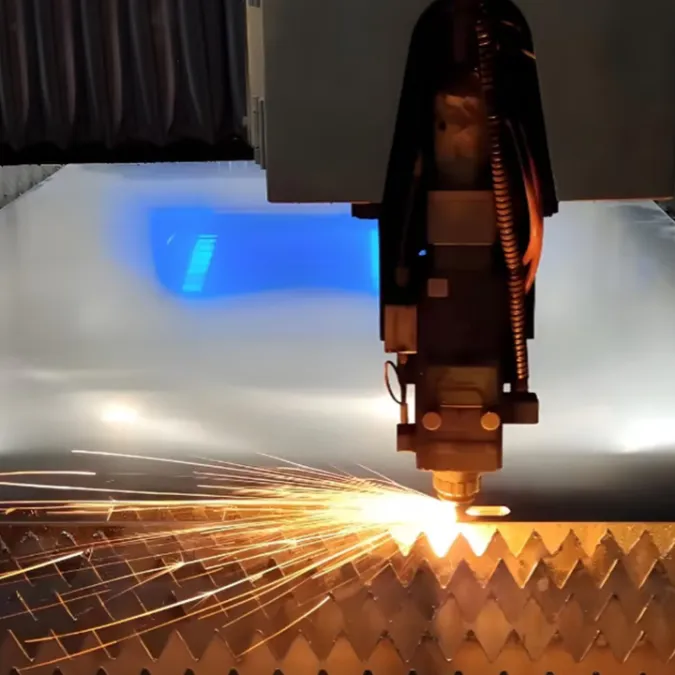

Step 3: High-Precision Laser Cutting

Technical Standards:

Use fiber laser cutting systems (power 1.5–6kW) with cutting precision of ±0.05mm, cut edge verticality ≤0.1mm, and heat-affected zone control within 0.15mm. Cutting speed is optimized dynamically based on material: stainless steel 3–5m/min, aluminum alloy 5–8m/min.

Quality Control Points:

- Cutting burr height should not exceed 0.1mm (GB/T 11344).

- Hole diameter should be ≥1.2 times the material thickness to prevent deformation.

- Immediate deburring after cutting to prevent stress concentration during subsequent bending.

Step 4: CNC Bending & Forming

Technical Standards:

CNC bending machine with specialized dies, angle repeatability of ±0.3°, and compensation for springback using software. Minimum bending radii: stainless steel R ≥ 1.0t, aluminum R ≥ 0.8t.

Quality Control Points:

- Parallelism error between bending line and cutting edge should be ≤0.2mm.

- Cumulative error of multiple bends should be controlled within ±0.5mm.

- After bending, flatness should be checked: ≤0.5mm/m (GB/T 1184).

Step 5: Precision Welding & Structural Reinforcement

Technical Standards:

- Stainless steel: TIG welding (ISO 4063), argon purity ≥99.99%, weld height 0.5–1.0mm.

- Aluminum alloy: MIG pulse welding, preheating 80–120°C to prevent cracks.

- Welding strength should be ≥80% of base material (AWS D1.1), with 100% PT testing (ASTM E165) on critical welds.

Quality Control Points:

- Weld surface should be free from undercuts, porosity, and incomplete fusion (refer to ISO 5817 B level).

- Sealed welds must undergo helium mass spectrometry leak testing (leak rate ≤1×10⁻⁶ Pa·m³/s).

- Passivation treatment (ASTM A967) after welding to restore the corrosion resistance of stainless steel.

Step 6: Full-Process Non-Destructive Testing

Technical Standards:

Establish a three-level inspection system (IQC/IPQC/OQC):

- Dimensions: 3D coordinate measurement machine (accuracy ±0.003mm).

- Welds: Penetrant Testing (PT) + Ultrasonic Testing (UT, ASTM E164).

- Surface: Gloss, coating thickness, adhesion (ASTM D3359).

Quality Control Points:

- Critical dimensions must meet a CPK ≥ 1.33, ensuring controlled process capability.

- Testing data must be traceable, generating a digital quality inspection report.

- Non-conforming products are segregated and marked, and 8D root cause analysis is implemented.

Step 7: Specialized Surface Treatment

Technical Standards:

| Process | Coating Thickness | Adhesion Quality | Salt Spray Test | Standard Reference |

| Powder Coating | 60–80μm | 0 Grade | ≥500h | ASTM D3359 |

| Fluorocarbon Coating | 30–40μm | 0 Grade | ≥2000h | AAMA 2605 |

| Anodizing | 10–25μm | — | ≥1000h | ASTM B117 |

| Zinc-Nickel Plating | 8–15μm | 0 Grade | ≥720h | ASTM B841 |

Quality Control Points:

- Color difference ΔE ≤ 0.8 (CIE Lab * standard).

- Coating thickness uniformity: range ≤10μm.

- For outdoor applications, prioritize fluorocarbon or anodizing to avoid UV degradation of powder coatings.

Step 8: Final Inspection, Packaging & वितरण

Technical Standards:

Full project final inspection:

- Dimension verification (critical holes ±0.15mm).

- Protection level testing (IP65/IP66 according to IEC 60529).

- Packaging complies with ISTA 3A:2021, including anti-static pearl cotton lining and reinforced wooden boxes.

Quality Control Points:

- Provide material certificates, salt spray reports, dimension reports, and compliance declarations (RoHS/REACH) with shipments.

- Packaging labels include batch numbers, production dates, and protection levels, supporting full traceability.

- Perform 100% visual inspection before shipment to eliminate risk of transportation damage.

Professional Manufacturing, Trusted Delivery

ShiJie has been dedicated to the custom metal enclosure industry, strictly adhering to the ISO 9001 quality management system. We align our processes with IEC, ASTM, GB, and other international and domestic standards throughout the production chain. Our custom enclosure solutions cater to industries like self-service terminals, industrial controls, and medical devices, offering protection levels from IP54 to IP67.

“Rigorous process control and transparent quality traceability are the cornerstones of ShiJie’s trustworthiness with global clients.”— Quality Control Manager

Explore more custom cases and technical solutions:

Website: https://sjenclosure.com/custom-enclosure/

Contact us:

- Phone: +86 150 1876 6189

- Email: मैनेजर@tongruplay.com

ShiJie Metal Enclosures — Precision Engineering for Global Applications

Specializing in Custom Metal Enclosures • Process as Standard • Quality You Can Verify