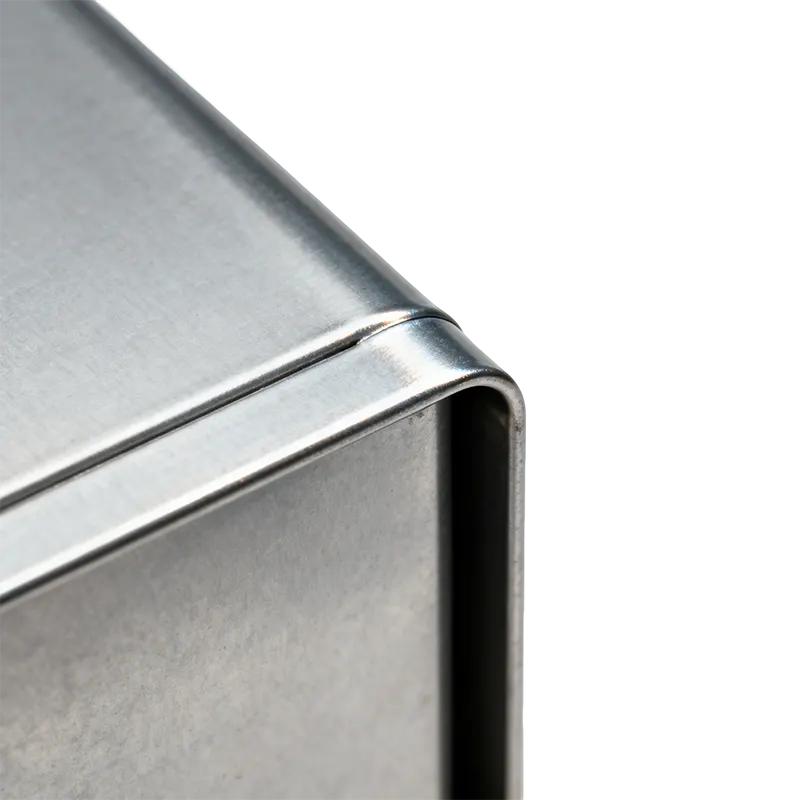

Для стандартных корпусов, оцинкованная сталь – надежный выбор. Защитный слой цинка на поверхности значительно повышает устойчивость к коррозии.. Это идеал, доступное решение для внутренних и коммунальных помещений, где базовая защита — это все, что вам нужно..

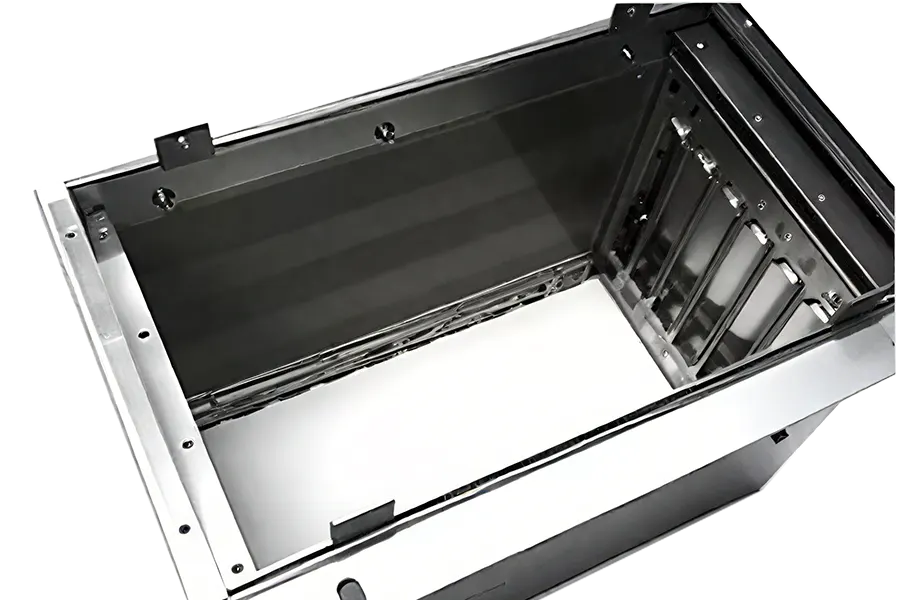

Как опытные производители корпусов из листового металла, мы предлагаем полный спектр вариантов материалов — от нержавеющей стали и алюминия до углеродистой и оцинкованной стали — чтобы обеспечить идеальный баланс производительности вашего проекта., долговечность, и стоимость.

| Материал | Основные функции | Лучшие приложения | Преимущества | Ограничения |

|---|---|---|---|---|

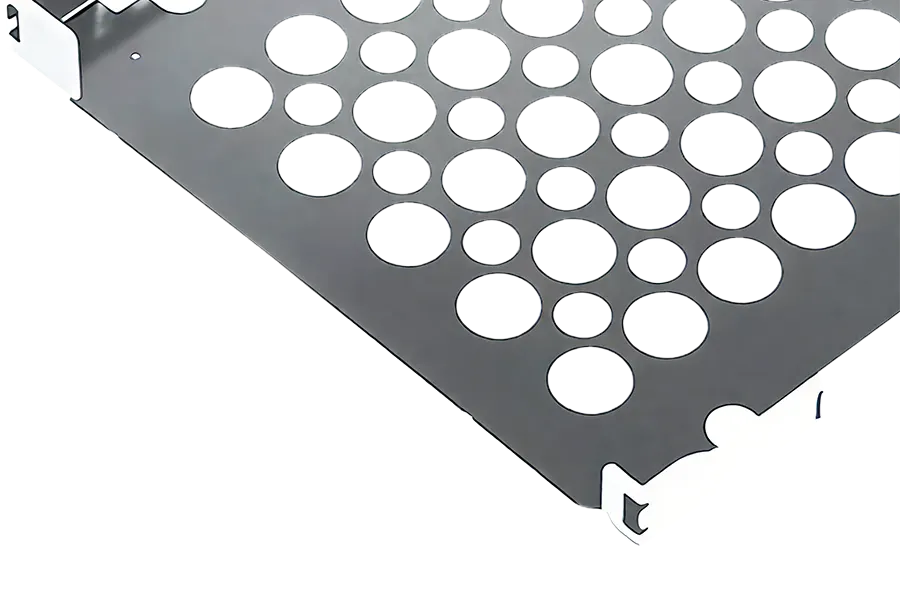

| Листовой металл | Высокая точность (±0,001 мм), универсальное изготовление | Гибкий, масштабируемое производство | Электроника, телекоммуникации, панели управления | Защита от коррозии зависит от покрытия |

| Нержавеющая сталь (304/316л) | Премиальная устойчивость к коррозии, гигиенический | Еда, медицинский, открытый, marine | Долгоиграющий, устойчивый к атмосферным воздействиям | Более высокая стоимость |

| Алюминий | Легкий, проводящий, хороший отвод тепла | Аэрокосмическая промышленность, автомобильный, портативные устройства | Легкое анодирование, Экранирование электромагнитных помех | Менее жесткий |

| Оцинкованная сталь | Цинковое покрытие для базовой защиты от коррозии. | Электрический, внутренние корпуса | Экономичный, зрелый процесс | Ограниченная долговечность на открытом воздухе |

| Углеродистая сталь | Сильный, жесткий, доступный | Тяжелая техника, энергетические системы | Высокая прочность, грузоподъемность | Склонен к ржавчине, без покрытия |

| Пользовательские материалы | Гибкий (медь, сплавы, титан) | Специализированные отрасли | С учетом потребностей | Расходы & время выполнения варьируется |

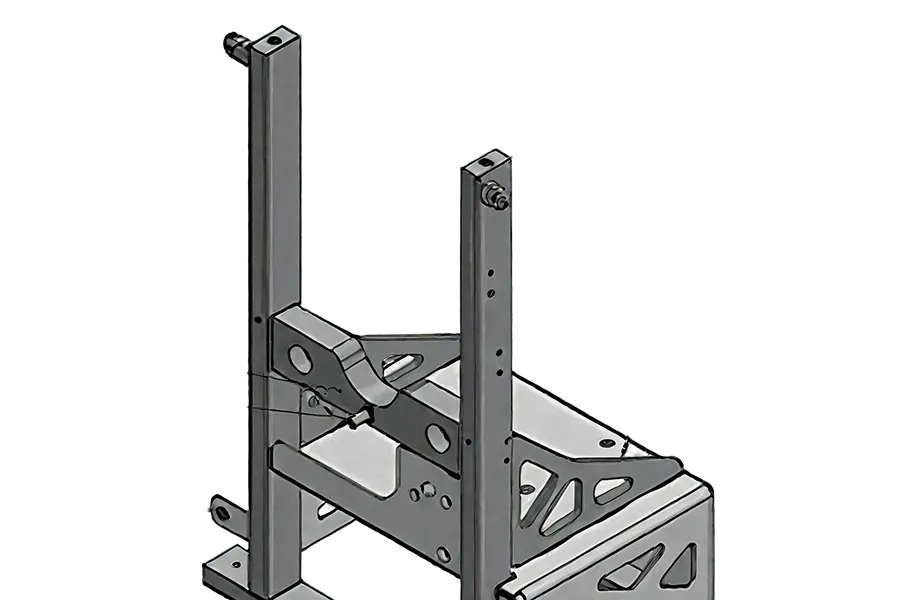

Наш пятиэтапный процесс позволяет нам гарантировать качество и своевременную доставку для каждого проекта, который мы реализуем как ведущий производитель корпусов из листового металла..

Анализируем ваши технические требования, бюджет, и сроки, чтобы предложить оптимальную конструкцию корпуса.

После анализа ваших технических требований, бюджет, и график, мы предоставляем подробное и прозрачное предложение для вашего обзора, обеспечение ясности перед переходом к прототипированию и проверке.

Функциональный прототип быстро создается для тестирования., подтвердить, и утвердить перед массовым производством.

Ваш заказ производится в больших количествах с несколькими контрольными точками контроля качества., от проверки материалов до окончательной сборки.

Проводим финальную системную интеграцию, тщательное тестирование, и надежная упаковка для своевременной доставки по всему миру..

Нужен ли вам производитель шкафов из нержавеющей стали?, поставщик алюминиевых шкафов, или надежный партнер по изготовлению корпусов из листового металла OEM, SHIJIE предлагает индивидуальные решения с быстрым отбором проб и своевременной доставкой..

Сквозной контроль: Проектирование → изготовление → сборка → доставка.

Гибкая обработка заказов: От прототипирования к крупносерийному производству

Глобальная доставка с 99.5% ставка за своевременность.

Нам доверяют торговые компании, разработчики проекта, и владельцы брендов.

*Мы уважаем вашу конфиденциальность и вся информация защищена.