When standard materials like carbon steel or aluminum aren’t enough, SHIJIE offers a wide range of custom options. We can source and fabricate enclosures using specialized materials to meet your project’s unique demands.

Our flexible material selection ensures your project is built with the perfect material for its specific function and environment.

It seems we can't find what you're looking for.

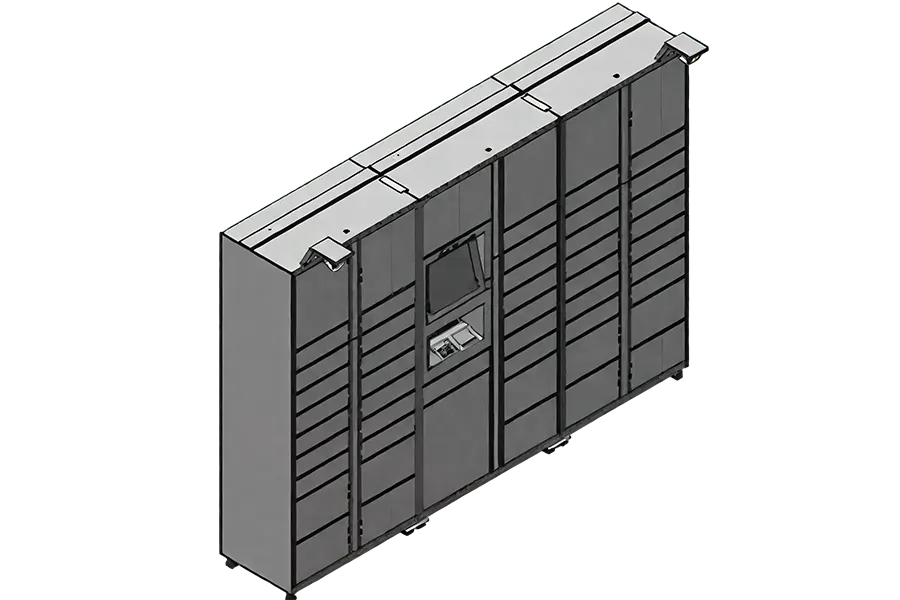

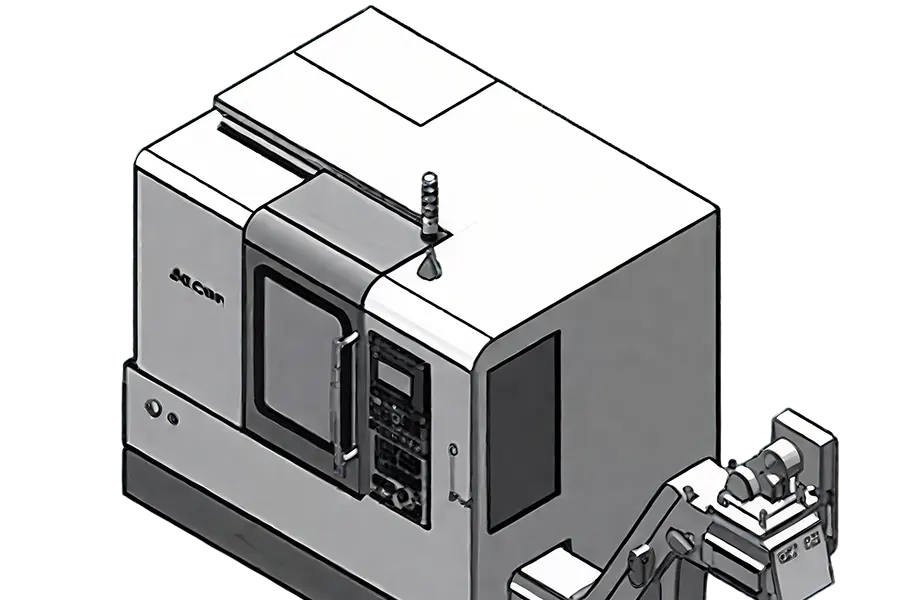

Come produttori esperti di custodie in lamiera, offriamo una gamma completa di opzioni di materiali, dall'acciaio inossidabile e alluminio all'acciaio al carbonio e zincato, per garantire che il tuo progetto abbia il perfetto equilibrio tra prestazioni, durabilità, e costo.

| Materiale | Caratteristiche principali | Le migliori applicazioni | Vantaggi | Limitazioni |

|---|---|---|---|---|

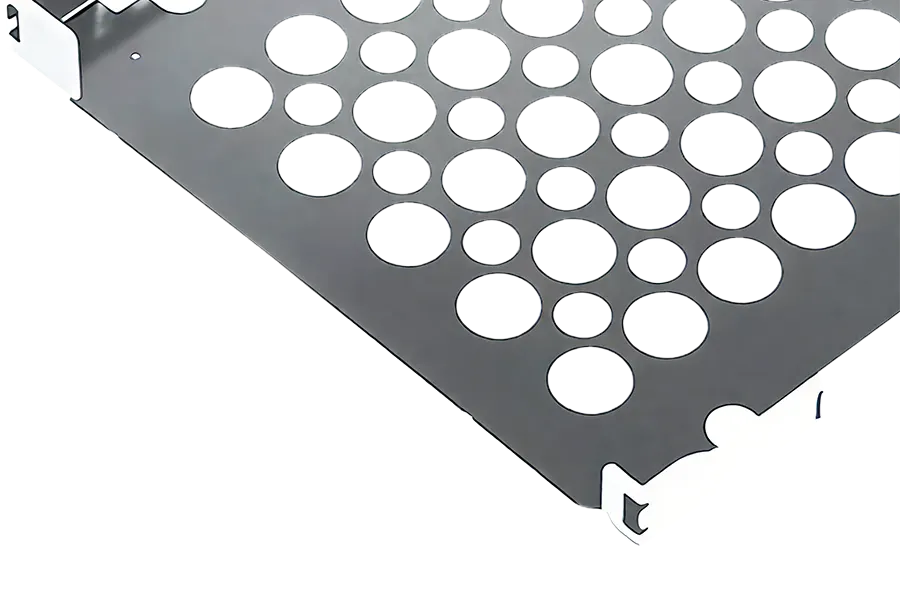

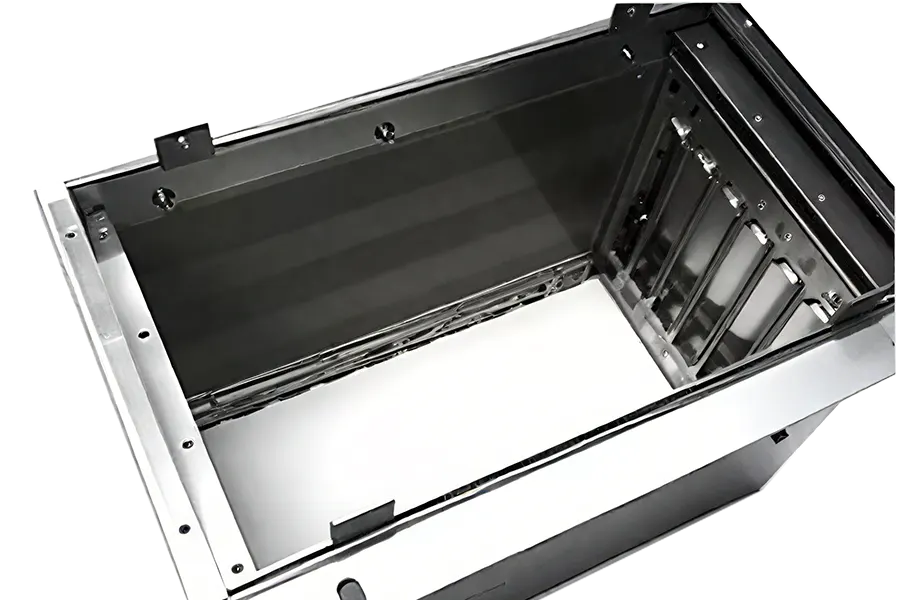

| Lamiera | Alta precisione (±0,001 mm), fabbricazione versatile | Flessibile, produzione scalabile | Elettronica, telecomunicazioni, pannelli di controllo | La protezione dalla corrosione dipende dal rivestimento |

| Acciaio inossidabile (304/316l) | Eccellente resistenza alla corrosione, igienico | Cibo, medico, all'aperto, marino | Di lunga durata, resistente alle intemperie | Costo più elevato |

| Alluminio | Leggero, conduttivo, buona dissipazione del calore | Aerospaziale, automobilistico, dispositivi portatili | Anodizzazione facile, Schermatura EMI | Meno rigido |

| Acciaio zincato | Rivestimento in zinco per una protezione base dalla corrosione | Elettrico, custodie per interni | Conveniente, processo maturo | Durata all'aperto limitata |

| Acciaio al carbonio | Forte, rigido, conveniente | Macchinari pesanti, sistemi di potere | Alta resistenza, capacità di carico | Soggetto alla ruggine senza rivestimento |

| Materiali personalizzati | Flessibile (rame, leghe, titanio) | Industrie specializzate | Su misura per le esigenze | Costo & i tempi di consegna variano |

It seems we can't find what you're looking for.

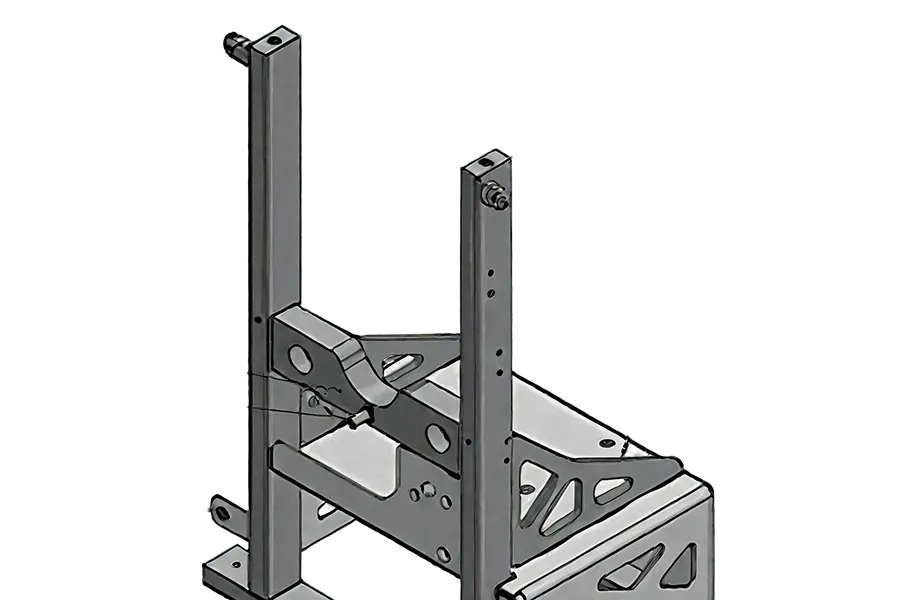

Il nostro processo in 5 fasi è il modo in cui garantiamo qualità e consegna puntuale per ogni progetto che intraprendiamo come produttore leader di custodie in lamiera.

Analizziamo le tue esigenze tecniche, bilancio, e tempistica per proporre un design ottimale della custodia.

Dopo aver analizzato i tuoi requisiti tecnici, bilancio, e cronologia, forniamo un preventivo dettagliato e trasparente per la tua recensione, garantire chiarezza prima di passare alla prototipazione e alla validazione.

Viene prodotto rapidamente un prototipo funzionale da testare, convalidare, e approvare prima della produzione di massa.

Il tuo ordine viene prodotto su larga scala con più controlli di qualità, dall'ispezione dei materiali all'assemblaggio finale.

Eseguiamo l'integrazione finale del sistema, test rigorosi, e un imballaggio sicuro per una consegna globale tempestiva.

Se hai bisogno di un produttore di armadi in acciaio inossidabile, un fornitore di armadi in alluminio, o un partner affidabile per la fabbricazione di custodie in lamiera OEM, SHIJIE fornisce soluzioni su misura con campionamento rapido e consegna puntuale.

Controllo end-to-end: Progettazione → fabbricazione → assemblaggio → consegna.

Gestione flessibile degli ordini: Dalla prototipazione alla produzione su larga scala

Consegna globale con 99.5% tariffa puntuale.

Scelto dalle aziende commerciali, sviluppatori del progetto, e proprietari di marchi.

*Rispettiamo la tua riservatezza e tutte le informazioni sono protette.