Hersteller kundenspezifischer Metallgehäuse

SHIJIE bietet maßgeschneiderte Metallgehäuselösungen aus einer Hand für eine breite Produktpalette, inklusive Metallboxen, Metallgehäuse, Metallschränke, und Schutzgehäuse – gebaut, um den unterschiedlichen Anwendungsanforderungen gerecht zu werden.

Warum sollten Sie SHIJIE als Ihren Hersteller von Metallgehäusen wählen?

- Zuverlässige Qualität: Qualitätsmanagementsystem nach ISO 9001

- Schnelle Reaktion: Erhalten Sie innerhalb von 24 Stunden ein Angebot 24 Stunden nach Bestätigung der Anforderungen.

- Professionelle Ingenieure: Erhalten Sie hier eine Konstruktionszeichnung für Ihr individuelles Metallgehäuseprojekt 3 Tage

- Pünktliche Lieferung: Große Produktionskapazitäten und umfangreiche Erfahrung in der Individualisierung gewährleisten stabile Lieferzeiten von 15–25 Tagen

Über SHIJIE- Ihr vertrauenswürdiger Hersteller von kundenspezifischen Metallgehäusen in China

SHIJIE bietet Präzisionsblechfertigungsdienstleistungen für verschiedene Produkte an, Strukturen, und Komponenten.

Mit fortschrittlicher Ausrüstung, ein erfahrener R&D-Team in der Struktur, Produkt, und Softwaredesign, und Facharbeiter durchschnittlich 12+ jahrelange Erfahrung, Wir liefern hochwertige Gehäuse mit komplexen und präzisen Funktionen.

Warum sollten Sie sich für SHIJIE entscheiden?

- Zertifizierte Qualität: ISO 9001 konformes Management.

- 24h Antwort: Schnelle Angebote nach Bedarfsbestätigung.

- 3-Tagesdesign: Schnelle Bearbeitung individueller Projektzeichnungen.

- Stabile Lieferung: Garantierte Lieferzeiten von 15–25 Tagen.

Entdecken Sie die kundenspezifischen Blechgehäuselösungen von SHIJIE

Wir verfügen über umfangreiche Erfahrung mit kundenspezifischen Metallgehäusen für eine Vielzahl von Branchen und Produkten – teilen Sie uns Ihre Anforderungen mit, und wir setzen Ihre Ideen in die Realität um.

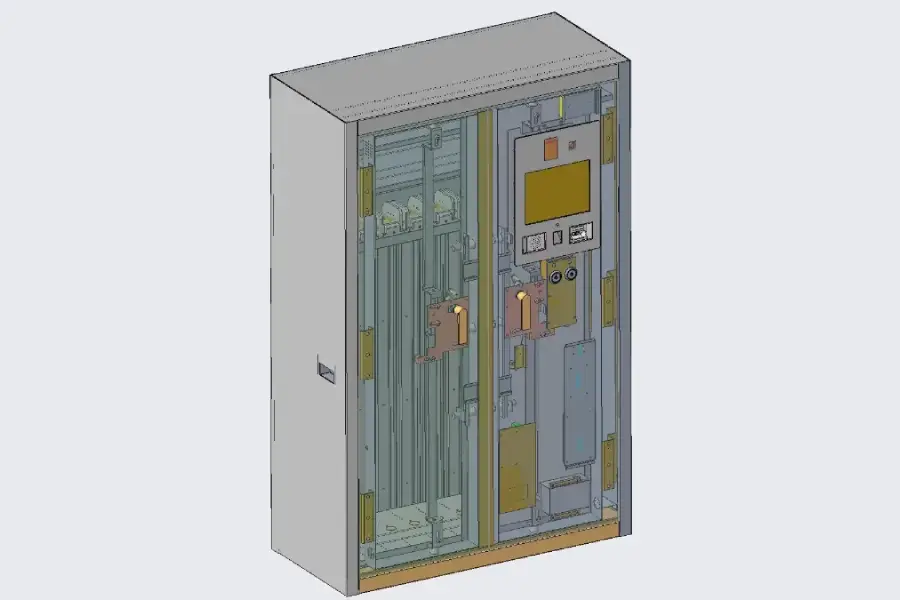

Elektrische Gehäuse

Anpassbar anhand von Zeichnungen mit Ausschnitten, Abmessungen, und Montagemöglichkeiten – ideal für die Stromverteilung, Steuerungssysteme, und Geräteschutz.

Freistehende Elektrogehäuse aus Kohlenstoffstahl

Starke Struktur und kostengünstig; optionaler Sockel/Sockel, Belüftung, und Filterlösungen – gut geeignet für die industrielle Steuerung und Energieverteilung.

Wandgehäuse aus Aluminium

Leicht und korrosionsbeständig, mit Wandmontagedesign und individuellen Ausschnitten – ideal für die Telekommunikation, Instrumente, und Innenausstattung.

Edelstahlgehäuse

Korrosionsbeständig und leicht zu reinigen; Erhältlich mit gebürsteter oder sandgestrahlter Oberfläche – ideal für den Außenbereich, Lebensmittelqualität, und Umgebungen mit hoher Luftfeuchtigkeit.

Gehäuse mit Rollen

Leicht zu transportieren und zu warten; Rollentyp und Tragfähigkeit können individuell angepasst werden – ideal für Werkstätten und temporäre Einsätze.

Kundenspezifische Metallgehäuse mit Lichtleisten

Lichtleistenintegration mit interner Kabelführung; anpassbare Länge, Montageorte, und Kabelausgänge – ideal zur Anzeige und Geräteanzeige.

Kundenspezifische Metallgehäuse mit LED

Unterstützt die Integration von LED-Modulen/Anzeigen und Lichtstreuungsdesigns mit Fenstern – ideal für Statusanzeige und Mensch-Maschine-Interaktion.

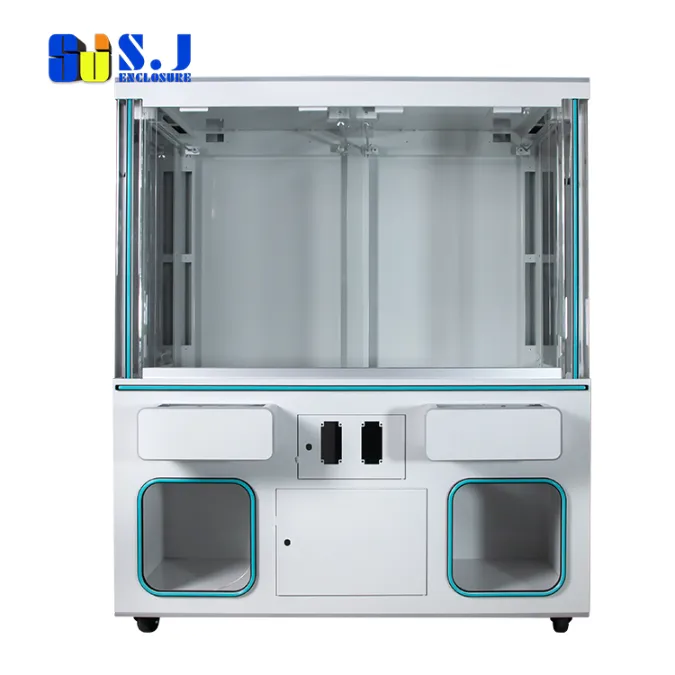

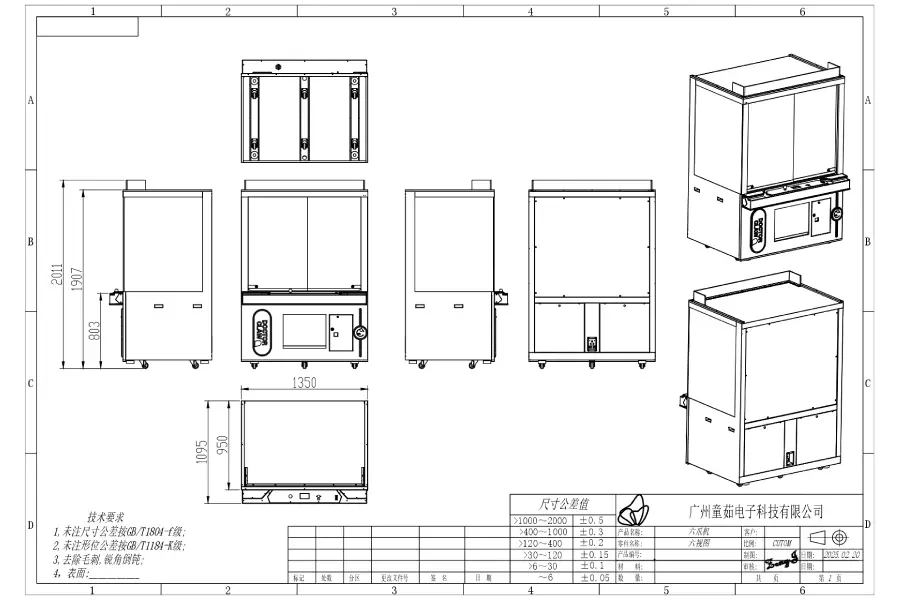

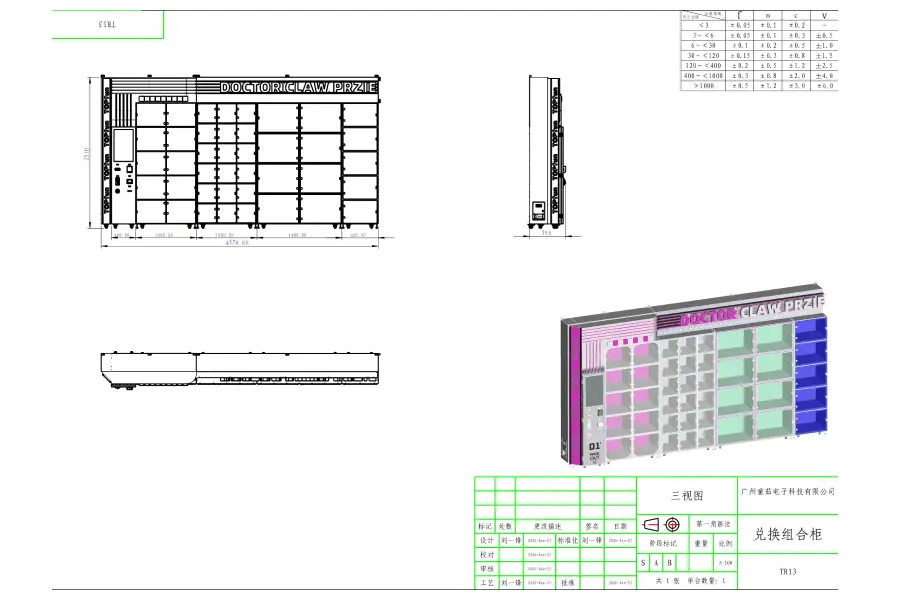

Kundenspezifische Gehäuse für Verkaufsautomaten

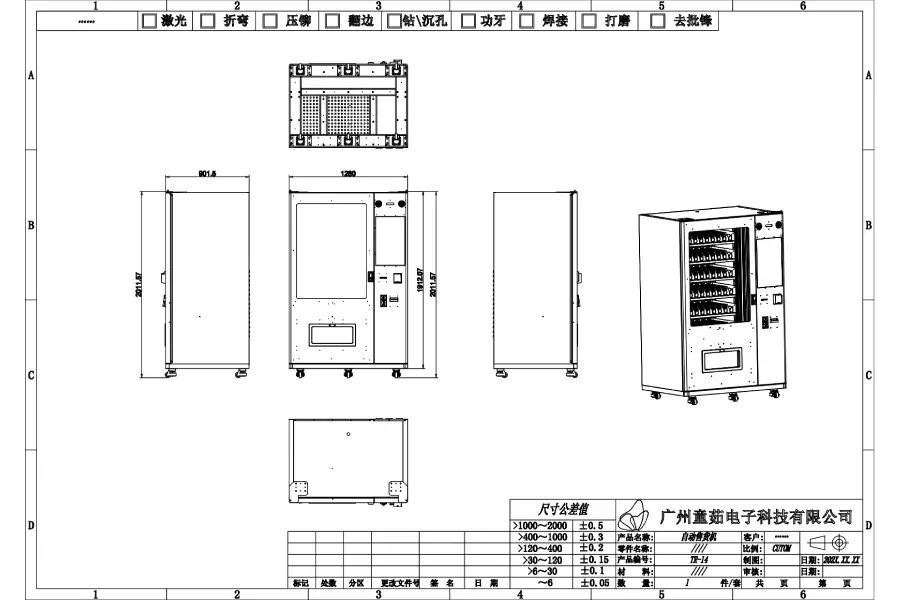

Anpassbare Türstruktur, Werbetafeln, und Belüftungsausschnitte; Unterstützt die komplette Maschinenmontage – ideal für Selbstbedienungsgeräte im Einzelhandel.

Smart Locker-Gehäuse

Kundenspezifische Konfigurationen für mehrere Türen mit Verriegelungspositionen und interner Verkabelungsanordnung; je nach Anwendung skalierbar – ideal für Paketschließfächer und gemeinsame Lagerlösungen.

Von Ihrem Hersteller von Blechgehäusen bediente Branchen

Wir bieten vollständig maßgeschneiderte Blech- und Gehäusefertigungsdienstleistungen – von der Materialauswahl bis zur kompletten Montage. Unser Anpassungsumfang umfasst:

Kundenspezifische Metallgehäuse

SHIJIE bietet maßgeschneiderte Metallgehäuse für jede Anwendung und Branche. Unabhängig von Ihren Anforderungen oder Einsatzszenarien, Wir liefern nicht standardmäßig, vollständig maßgeschneiderte Metallgehäuse, die genau Ihren Anforderungen entsprechen.

Lagerschränke

Alle Schließfachgrößen und -konfigurationen können individuell angepasst werden. SHIJIE verfügt über umfangreiche Erfahrung in Smart-Locker-Projekte, Bereitstellung nicht nur der Herstellung von Metallschränken, sondern auch Systementwicklung für komplette Maschine & Gehäuselösungen.

Elektrische Gehäuse

Wir entwerfen und fertigen hochwertig, Präzisionsmetallgehäuse für elektrische und industrielle Geräte, die den Anforderungen entsprechen Es gibt keine Standards.

Jedes Gehäuse bietet einen hervorragenden Staubschutz, Wasser, und Korrosion, mit End-to-End-Anpassung Abdeckdesign, Materialauswahl, Produktion, und Montage.

Gehäuse für gewerbliche Geräte

Wir produzieren Blechgehäuse für verschiedene kommerzielle Produkte wie z Verkaufsautomaten, Werbedisplays, Geldautomaten, Klauenmaschinen, und große Arcade-Ausrüstung.

Für Verkaufs- und Klauenautomaten, SHIJIE bietet vollständige Produktentwicklung mit bewährt, Erfahrung in der Massenproduktion.

Aktuelle kundenspezifische Metallgehäuseprojekte

SHIJIE bietet maßgeschneiderte Metallgehäuselösungen für eine Vielzahl von Branchen. Senden Sie uns Ihre Anforderungen, und wir liefern eine maßgeschneiderte Lösung mit einem schnellen Angebot.

Kundenspezifische Metallgehäuse

Gebaut, um Ihren technischen Spezifikationen und erforderlichen Schutzniveaus zu entsprechen. Wir konstruieren jedes Gehäuse so, dass eine zuverlässige Dichtungsleistung erreicht wird und die Belastungsanforderungen für reale Betriebsbedingungen erfüllt werden.

Kundenspezifische Gehäuse für Verkaufsautomaten

Wir fertigen Automatengehäuse individuell an und bieten passendes Zubehör sowie Montageleistungen an. Bei Bedarf, Wir können eine komplett montierte Lieferung liefern, betriebsbereiter Verkaufsautomat mit kompletten Funktionen.

Maßgeschneiderte Smart-Locker-Gehäuse

Modulare, intelligente Schließfachschränke in verschiedenen Größen und Türkonfigurationen, mit anpassbarem Erscheinungsbild. Wir können auch das für die Bereitstellung erforderliche intelligente Managementsystem bereitstellen.

So erhalten Sie ein Angebot von SHIJIE Within 24 Std

Wenn Sie die unten aufgeführten Details angeben können, Wir können Ihnen innerhalb von 24 Stunden ein Angebot zusenden 24 Std.:

- Teilen Sie Ihre Zeichnungen (oder Referenzfotos) und das Anwendungsszenario.

- Geben Sie das erforderliche Material und die erforderliche Oberflächenveredelung an

- Bestätigen Sie die Gehäuseabmessungen und die erforderliche Menge.

- Erklären Sie alle Sonderfunktionen oder benutzerdefinierten Funktionen, die Sie benötigen

Kundenspezifisches Gehäusezubehör & Komponenten

SHIJIE bietet alles, was Sie für ein voll funktionsfähiges kundenspezifisches Gehäuse benötigen – sodass jede Funktionsanforderung korrekt umgesetzt werden kann.

Wir bieten ein umfangreiches Sortiment an Gehäusezubehör an, Dazu gehören sowohl kundenspezifische Hardware als auch elektronische Komponenten, wie Klammern, Vordächer, DIN-Schienen, Lamellen, PDUs, Leiterplatten, LCD-Bildschirme, Rollen, und Türen aus gehärtetem Glas. Unsere Zubehöranpassung gewährleistet eine präzise Passform für jede individuelle Anwendung und jedes Installationsszenario.

Herstellungsprozess von Blechgehäusen

SHIJIE folgt einem strukturierten Produktionsablauf, der durch fortschrittliche Ausrüstung unterstützt wird, professionelle Ingenieure, Fachkräfte, und ein strenges Qualitätsmanagement – um sicherzustellen, dass jedes maßgeschneiderte Metallgehäuse mit gleichbleibender Präzision hergestellt wird, stabile Lieferzeiten, und zuverlässige Leistung.

1.Materialinspektion

Jede Charge wird streng kontrolliert, um eine qualifizierte Materialqualität sicherzustellen.

2.CNC-Schneiden

Ausgestattet mit fortschrittlichen Bystronic-Maschinen für Hochleistungsschneiden.

3.Laserschneiden

Schnittgenauigkeit von ±0,2 mm für saubere Kanten mit minimalen Graten.

4.Biegen

Biegegenauigkeit von ±0,5 mm, in der Lage, komplexe Kurven zu bilden.

5.Clinch / PEM-Einfügung

Präzises Verfahren zur Gewährleistung zuverlässiger Verbindungen und starker Befestigung.

6.Schweißen

Hohe Schweißgenauigkeit durch Fachkräfte, erfahrene Arbeiter.

7.Schleifen & Abschluss

Sorgt für einen reibungslosen Ablauf, Wohnung, und sauberes Aussehen für Ihr Metallgehäuse.

8.Montage

Monteure durchschnittlich 8+ Jahrelange Erfahrung, um perfekte Details an jedem Gehäuse zu gewährleisten.

9.Funktionstests

Für fertige Sonderanfertigungen, Wir führen vor dem Versand vollständige Funktionstests durch.

Material, das Sie für Ihr Blechgehäuse auswählen können

Dauerhaft & korrosionsbeständig, ideal für draußen & Anwendungen in Lebensmittelqualität

Leicht & hervorragende Wärmeableitung, Perfekt zur Energiespeicherung & Elektronik

Kostengünstig, rostbeständig, weit verbreitet in der Elektrotechnik & Industrielle Steuerung

Stark & zuverlässig, Geeignet für Innenschränke & Industrieboxen

Einschließlich EV-Ladeboxen, mobile Schließfächer, Modulare Gehäuse, Wetterfeste Außengehäuse

Ich kann nicht finden, was Sie brauchen? Kontaktieren Sie uns für weitere Informationen, die Ihren Anforderungen entsprechen

Anlagen und Maschinen zur Herstellung von Blechgehäusen von SHIJIE

SHIJIE ist mit fortschrittlichen Maschinen und Werkzeugen ausgestattet, um Präzision und Effizienz bei jedem Metallverarbeitungsprojekt zu gewährleisten.

- Laserschneidmaschinen

- Biegemaschinen

- CNC-Stanzmaschinen

- Schleifmaschinen

Materialoptionen für Ihre Blechgehäuse/-kästen/-schränke

- Verzinkter Stahl

- Aluminium

- Edelstahl

- Kohlenstoffstahl

Optionen zur Oberflächenveredelung

- Pulverbeschichtung

- Feuerverzinkung

- Siebdruck

- Elektrostatisches Sprühen

- Sandstrahlen

- Eloxieren

Projektgalerie eines vielseitigen Herstellers von Blechgehäusen

Entdecken Sie die von unserer Blechgehäusefabrik gelieferten Projekte, Wir präsentieren unser Fachwissen in verschiedenen Materialien, Integrationen, und hochwertige Oberflächen.