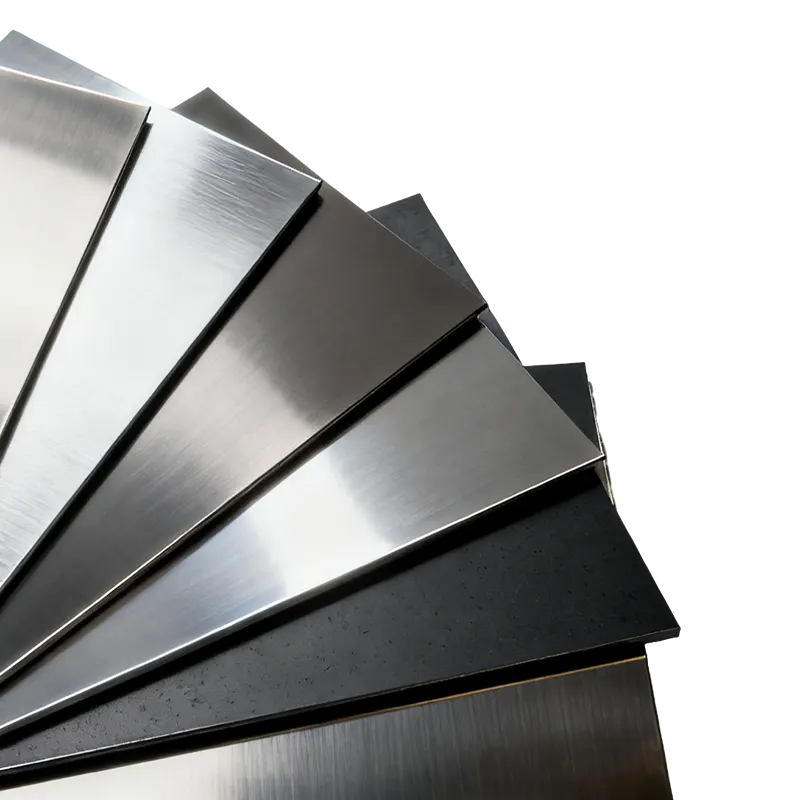

Sheet metal is the go-to material for enclosures because it perfectly balances strength, versatility, and cost. Its flexibility in cutting and forming lets us create just about any complex, high-precision design you can imagine.

Durable & corrosion-resistant, ideal for outdoor & food-grade applications

Cost-effective, rust-resistant, widely used in electrical & industrial control

Strong & reliable, suitable for indoor cabinets & industrial boxes

Stainless steel, aluminum, galvanized steel, and carbon steel — all processed with precision to meet diverse industry needs.

As experienced sheet metal enclosure manufacturers, we offer a full range of material options—from stainless steel and aluminum to carbon and galvanized steel—to ensure your project has the perfect balance of performance, durability, and cost.

| Material | Core Features | Best Applications | Advantages | Limitations |

|---|---|---|---|---|

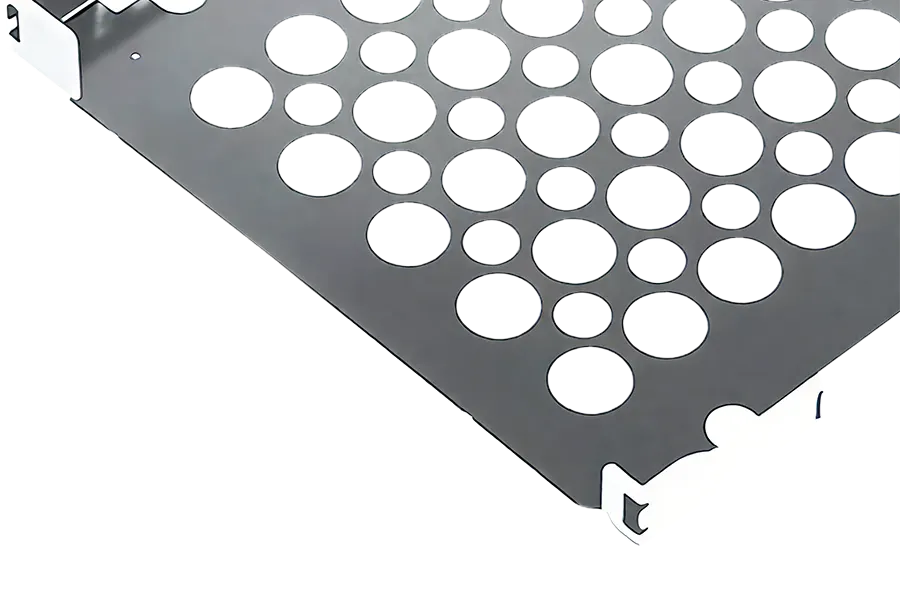

| Sheet Metal | High precision (±0.001mm), versatile fabrication | Flexible, scalable production | Electronics, telecom, control panels | Corrosion protection depends on coating |

| Stainless Steel (304/316L) | Premium corrosion resistance, hygienic | Food, medical, outdoor, marine | Long-lasting, weather-proof | Higher cost |

| Aluminum | Lightweight, conductive, good heat dissipation | Aerospace, automotive, portable devices | Easy anodizing, EMI shielding | Less rigid |

| Galvanized Steel | Zinc coating for basic corrosion protection | Electrical, indoor housings | Cost-efficient, mature process | Limited outdoor durability |

| Carbon Steel | Strong, rigid, affordable | Heavy machinery, power systems | High strength, load capacity | Rust-prone without coating |

| Custom Materials | Flexible (copper, alloys, titanium) | Specialized industries | Tailored to needs | Cost & lead time vary |

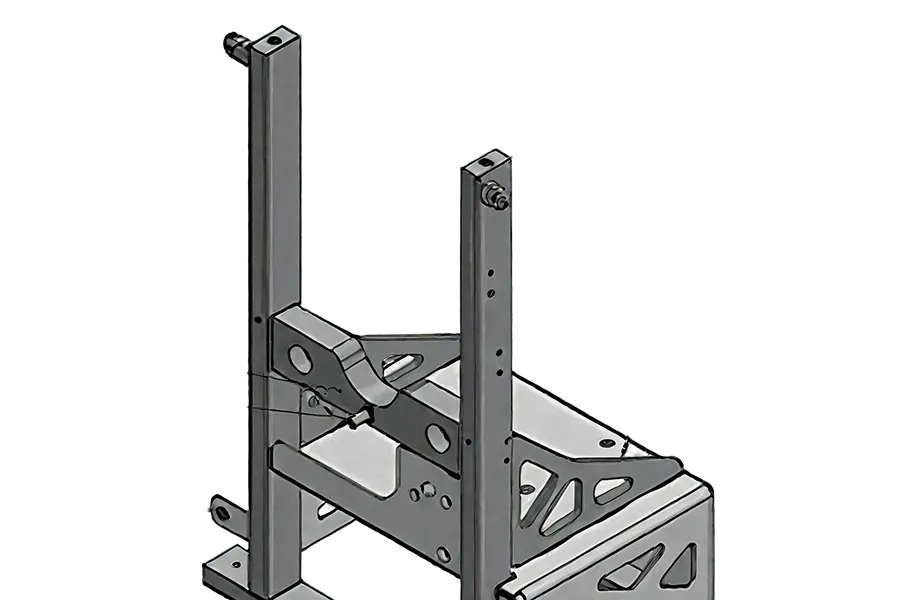

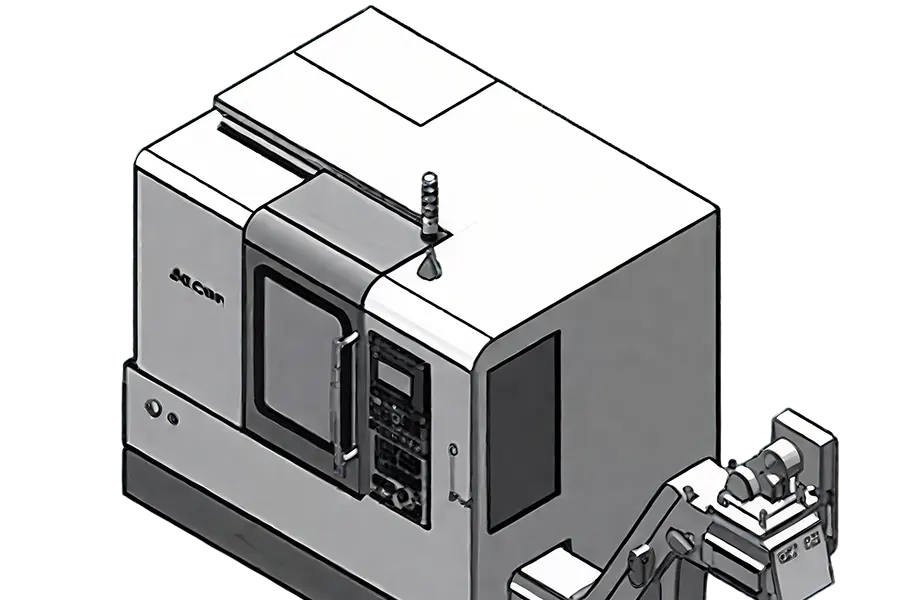

We analyze your technical requirements, budget, and timeline to propose an optimal enclosure design.

A functional prototype is rapidly produced for you to test, validate, and approve before mass production.

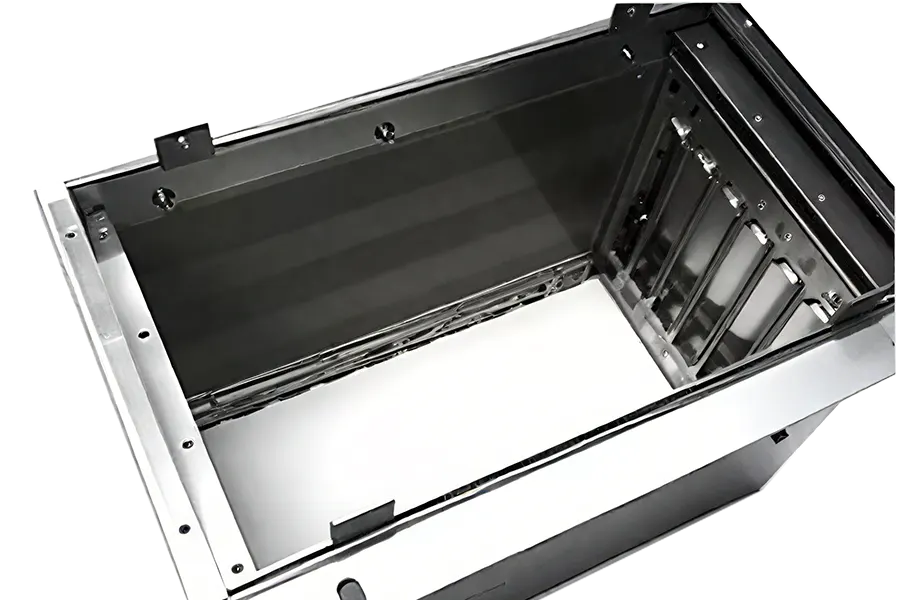

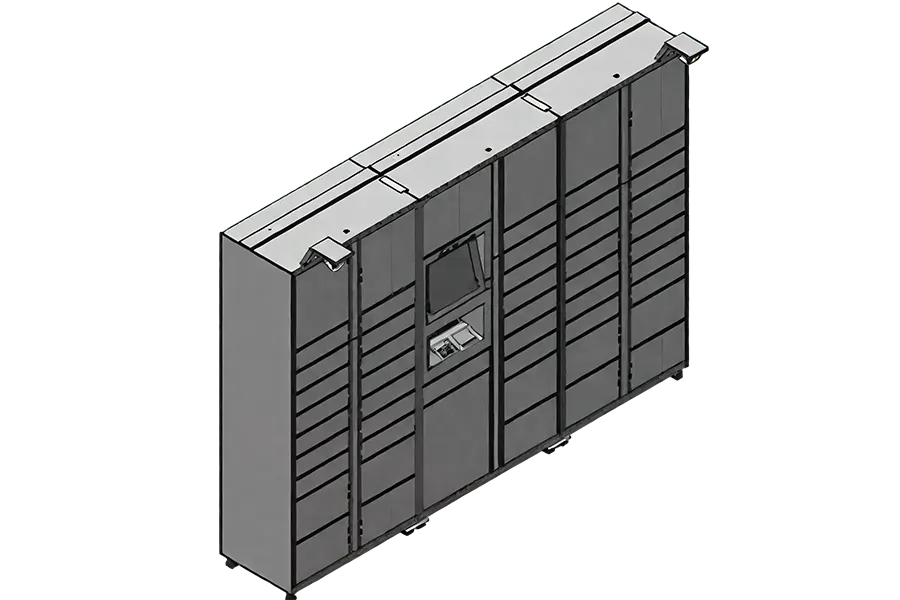

Your order is manufactured at scale with multiple quality control checkpoints, from material inspection to final assembly.

We perform final system integration, rigorous testing, and secure packaging for timely global delivery.

Whether you need a stainless steel cabinet manufacturer, an aluminum cabinet supplier, or a reliable partner for OEM sheet metal enclosure fabrication, SHIJIE provides tailored solutions with fast sampling and on-time delivery.

End-to-end control: Design → fabrication → assembly → delivery.

Flexible order handling: From prototyping to large-scale production

Global delivery with 99.5% on-time rate.

Trusted by trade companies, project developers, and brand owners.

*We respect your confidentiality and all information are protected.