When standard materials like carbon steel or aluminum aren’t enough, SHIJIE offers a wide range of custom options. We can source and fabricate enclosures using specialized materials to meet your project’s unique demands.

Our flexible material selection ensures your project is built with the perfect material for its specific function and environment.

It seems we can't find what you're looking for.

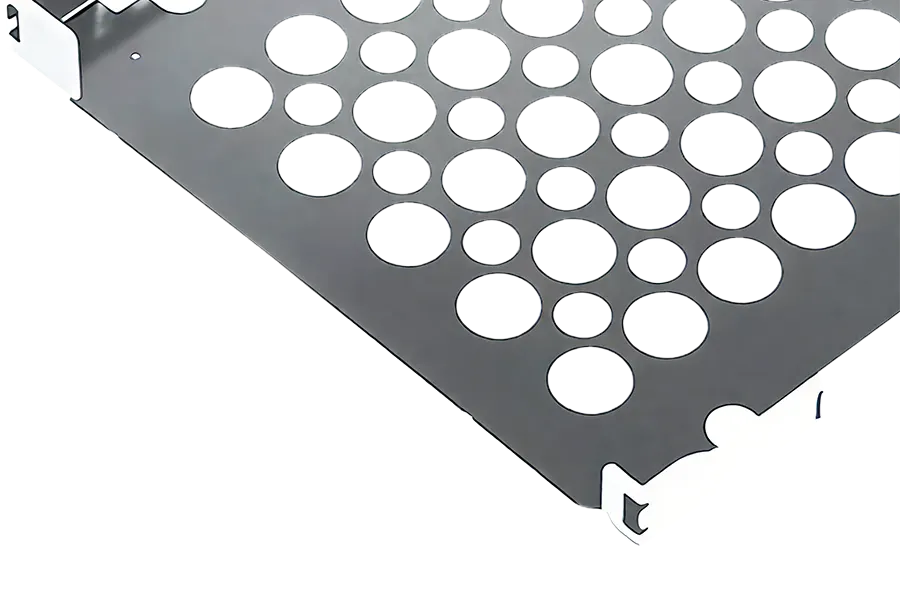

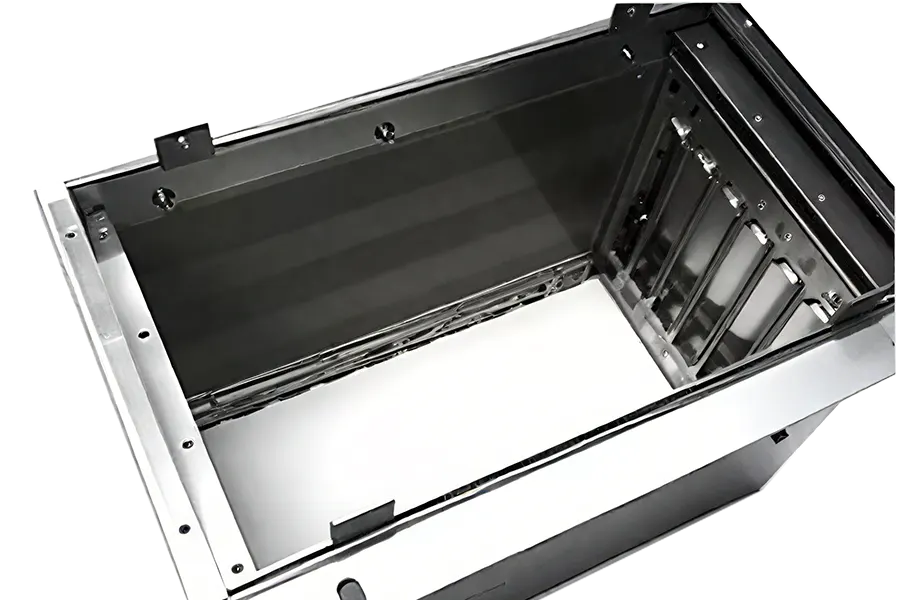

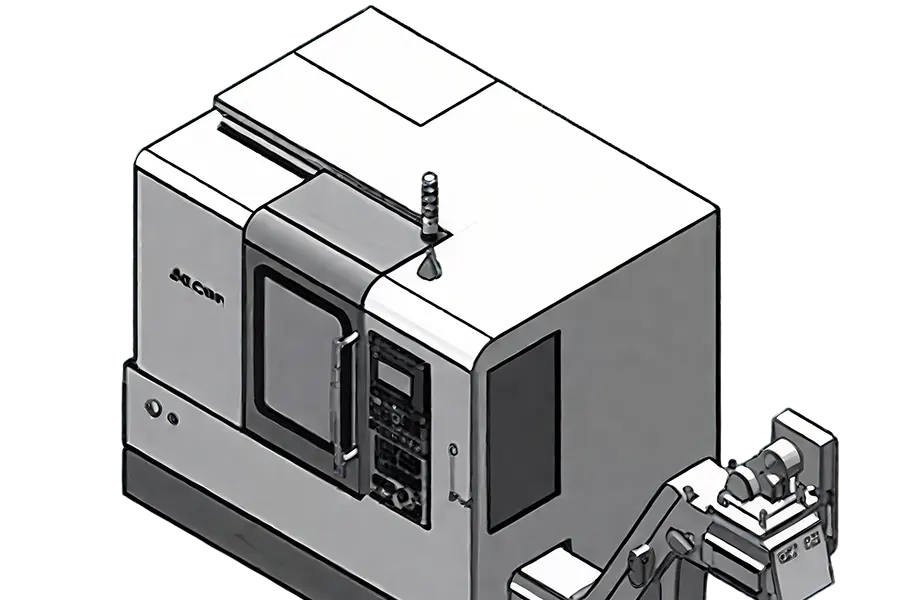

As experienced sheet metal enclosure manufacturers, we offer a full range of material options—from stainless steel and aluminum to carbon and galvanized steel—to ensure your project has the perfect balance of performance, durability, and cost.

| Material | Core Features | Best Applications | Advantages | Limitations |

|---|---|---|---|---|

| Sheet Metal | High precision (±0.001mm), versatile fabrication | Flexible, scalable production | Électronique, telecom, control panels | Corrosion protection depends on coating |

| Acier inoxydable (304/316L) | Premium corrosion resistance, hygienic | Food, medical, outdoor, marine | Long-lasting, weather-proof | Higher cost |

| Aluminium | Léger, conductive, good heat dissipation | Aerospace, automotive, portable devices | Easy anodizing, EMI shielding | Less rigid |

| Acier galvanisé | Zinc coating for basic corrosion protection | Electrical, indoor housings | Cost-efficient, mature process | Limited outdoor durability |

| Acier au carbone | Fort, rigid, affordable | Heavy machinery, power systems | High strength, load capacity | Rust-prone without coating |

| Custom Materials | Flexible (copper, alloys, titanium) | Specialized industries | Tailored to needs | Cost & lead time vary |

It seems we can't find what you're looking for.

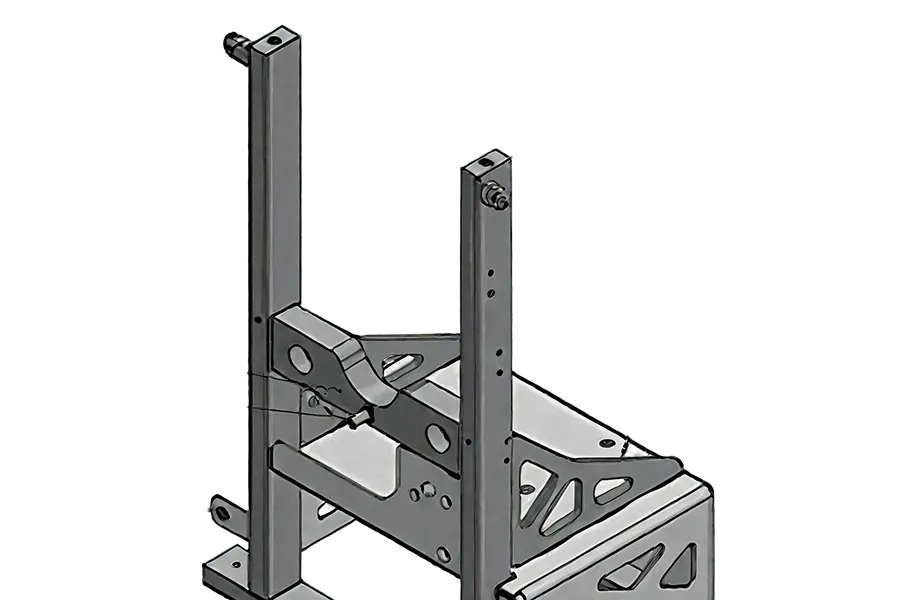

Notre processus en 5 étapes nous permet de garantir la qualité et la livraison dans les délais pour chaque projet que nous entreprenons en tant que fabricant leader de boîtiers en tôle..

Nous analysons vos besoins techniques, budget, et un calendrier pour proposer une conception de boîtier optimale.

Après avoir analysé vos besoins techniques, budget, et chronologie, nous fournissons un devis détaillé et transparent pour votre évaluation, assurer la clarté avant de passer au prototypage et à la validation.

Un prototype fonctionnel est rapidement réalisé pour que vous puissiez le tester, valider, et approuver avant la production de masse.

Votre commande est fabriquée à grande échelle avec plusieurs points de contrôle de qualité, de l'inspection des matériaux à l'assemblage final.

Nous effectuons l'intégration finale du système, des tests rigoureux, et un emballage sécurisé pour une livraison mondiale dans les délais.

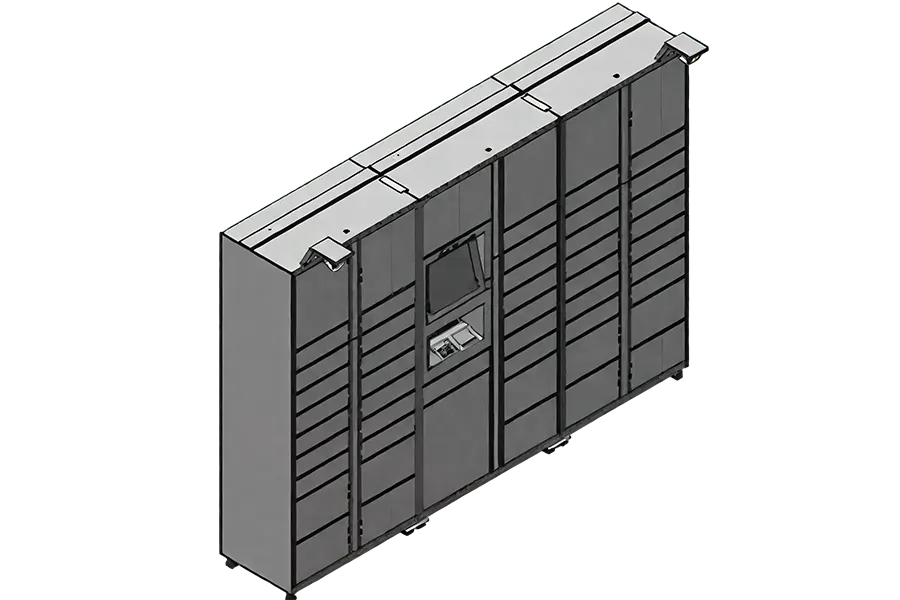

Que vous ayez besoin d'un fabricant d'armoires en acier inoxydable, un fournisseur d'armoires en aluminium, ou un partenaire fiable pour la fabrication de boîtiers en tôle OEM, SHIJIE fournit des solutions sur mesure avec un échantillonnage rapide et une livraison à temps.

Contrôle de bout en bout: Conception → fabrication → assemblage → livraison.

Gestion flexible des commandes: Du prototypage à la production à grande échelle

Livraison mondiale avec 99.5% taux de ponctualité.

Approuvé par les sociétés commerciales, développeurs de projets, et propriétaires de marques.

*Nous respectons votre confidentialité et toutes les informations sont protégées.